In industrial processes, precise flow measurement is critical for efficiency and safety. However, the accuracy of sensors can be compromised by improper installation. To ensure reliable performance, follow these expert guidelines for optimal sensor placement and setup:

| Avoid Mechanical Vibration Install the sensor away from vibration sources such as pumps or machinery. Vibrations can distort measurements and damage the sensor over time. For added stability, use a “support rod” to anchor the pipeline and valve firmly. The rod’s lower end should be fixed to a stable foundation, while the upper end secures the pipeline with a pipe clamp. Never use the sensor housing to support pipelines, valves, or pumps. |

| Mitigate Thermal Expansion Effects Process pipelines expand or contract with temperature changes. Avoid installing sensors near “expansion joints”, as pipeline deformation can introduce stress and measurement errors. |

| Eliminate Electromagnetic Interference Keep sensors far from high-power electromagnetic sources like motors or transformers. Industrial EMI can disrupt signal integrity, leading to inaccurate readings. |

| Ensure Proper Pipeline Alignment The sensor flange must be “coaxially connected” to the pipeline flange to prevent installation stress. Misalignment can strain the sensor, affecting long-term reliability. |

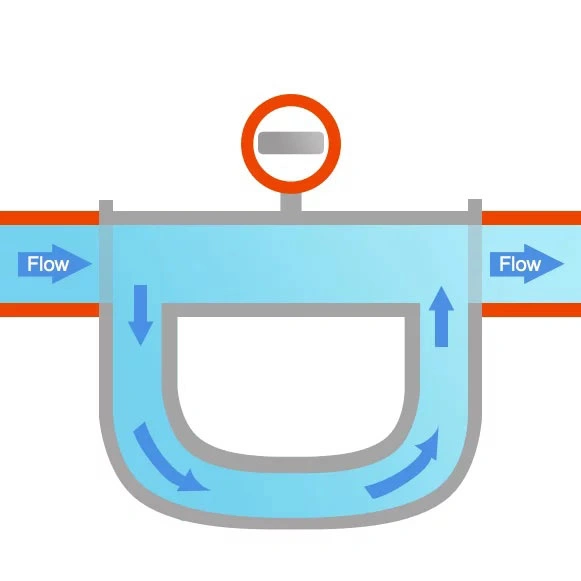

| Maintain Liquid-Filled Measuring Tube The sensor’s measuring tube must always be filled with liquid and maintain “back pressure”. Install the sensor at the “lower end of the pipeline” to prevent air pockets and ensure continuous liquid contact. |

| Install Shut-Off Valves Include shut-off valves upstream and downstream of the sensor for easy maintenance and calibration without disrupting the entire system. |

Why It Matters

Proper sensor installation maximizes accuracy, extends equipment lifespan, and reduces downtime. By adhering to these best practices, industries can achieve consistent, high-quality flow measurements in demanding environments.

For advanced sensor solutions designed for durability and precision, [Contact Us] your partner in reliable industrial measurement technology.