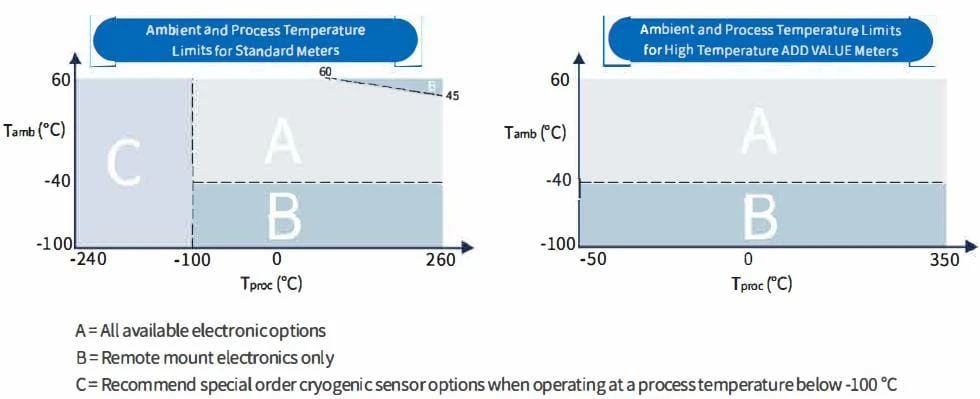

Process conditions are rarely perfect, but Add Value’s K-Series meters are built to perform in demanding thermal environments, from cryogenic lines to high-temperature reactors.

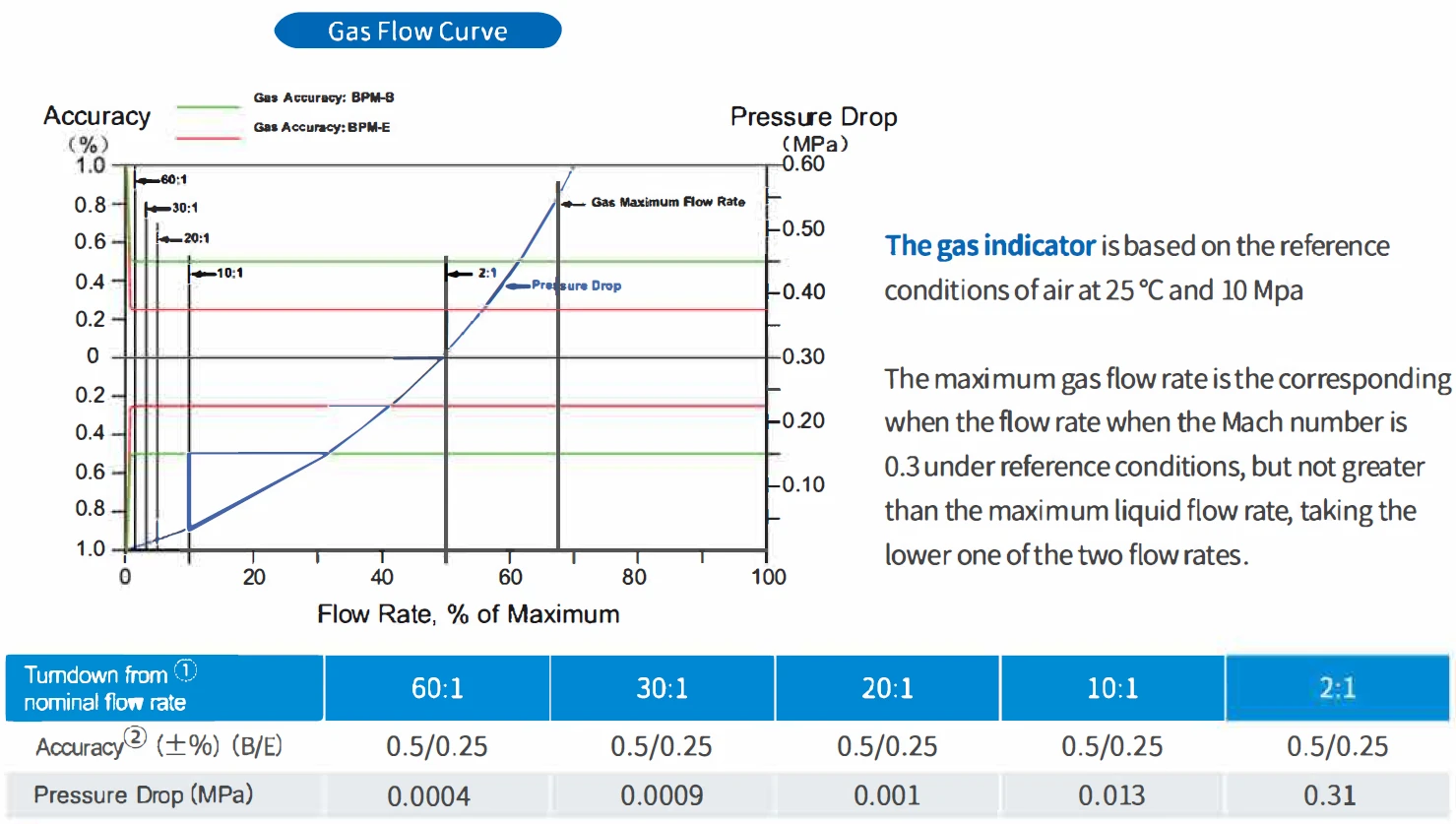

Gas measurement presents unique challenges due to compressibility, temperature variation, and low density. The Add Value K-Series overcomes these challenges with advanced flow tube design and signal processing:

When it comes to liquid measurement, Add Value’s K-Series Coriolis Mass Flow Meters stand out for their exceptional precision and minimal process disruption.

The KDM-HP is an ultra-high pressure vibrating tube liquid density meter specifically designed for challenging oilfield applications such as oil drilling, cementing platforms, and other high-pressure environments. It provides real-time, accurate monitorin

The KDM-S is a high-precision vibrating tube liquid density meter featuring a straight tube design that ensures low pressure loss, easy maintenance, and exceptional measurement accuracy. Designed to meet the needs of industries requiring strict cleanlines

The KDM-C is a compact vibrating tube liquid density meter designed for installations where space is limited but measurement performance must not be compromised. With a maximum measurement accuracy better than ±0.0001 g/cm³, the KDM-C combines laboratory-

The KDM is a standalone vibrating tube liquid density meter developed by Qingdao Add Value Flow Metering Co., Ltd., designed for real-time, online measurement of liquid density in a wide range of industrial environments. With a focus on stability, versati

In today's process automation landscape, real-time multi-parameter data is key to operational efficiency and product quality. A Coriolis mass flow meter delivers this capability by measuring mass flow, fluid density, and temperature in a single, compact